Contact Us

Tel:

E-mail:

Address:

Fengtun village, Jiaohe Town, Botou City, Cangzhou City, Hebei province

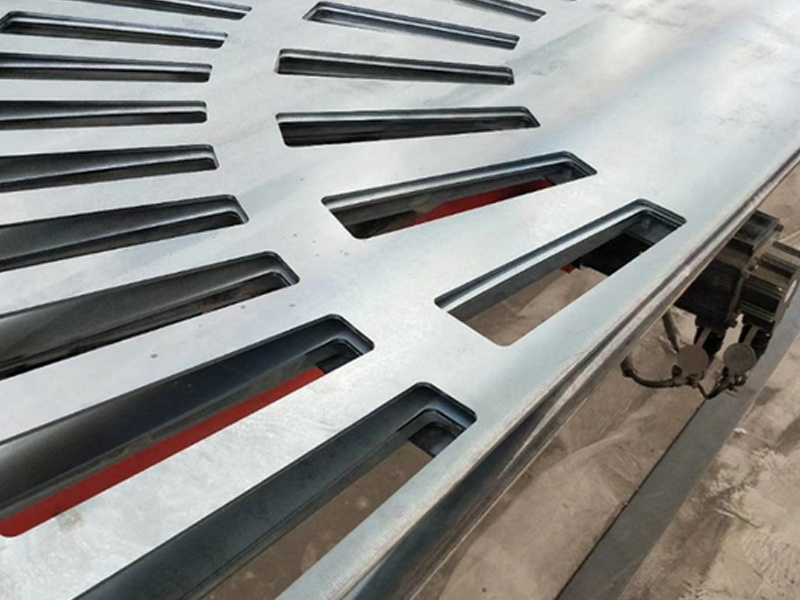

Pulse dust collector perforated plate

After several years' development,our products include screws, bolts, nuts and anchors. Over 95% of our products are exported to the overseas market, such as Europe. America and Southeast Asia.

- Commodity name: Pulse dust collector perforated plate

- Product description

-

Introduction

Dust plate is also called dust collector plate, dust steel partition. The flower plate refers to a steel partition plate with holes of the same size for installing dust filter bags. In the design of dust removal plate, the distance between the holes of the dust removal filter bag is mainly arranged, which is related to the bag diameter, bag length, dust nature, filtration speed and other factors. If the distance between the holes is too tight, the bottom of the filter bag will collide and wear each other, and part of the bottom of the filter bag will break within a few months. It will also cause the airflow in the box to rise too fast, resulting in an increase in soot emissions, too high local filtration load of the filter material and insufficient ash removal rate. For example, the center of the bag of a dust collector is 250mm from the wall plate, the distance between the fool blowing holes of the blowing pipe is 200mm, the diameter of the bag is 160mm, and the length is 6m. Because the distance between the bag and the bag is only 40mmm, the bottom of the filter bag collides with each other and wears, and the bottom of some filter bags is broken after several months of operation.

Technical parameters

Model of flower plate Overall dimension Aperture Plate thickness 16孔 750X756 133 3.75 24孔 756X1090 133 3.75 25孔 920X920 133 3.75 30孔 920X1090 133 3.75 36孔 1090X1090 133 3.75 42孔 1090X1260 133 3.75 48孔 1090X1430 133 3.75 64孔 1430X1430 133 3.75 72孔 1430X1600 133 3.75 80孔 1430X1770 133 3.75 96孔 1430X2110 133 3.75 100孔 1770X1770 133 3.75 120孔 1770X2110 133 3.75 140孔 1770X2450 133 3.75 150孔 1770X2620 133 3.75 160孔 1770X2790 133 3.75 170孔 1770X2960 133 3.75 180孔 1770X3130 133 3.75 200孔 1770X3470 133 3.75 220孔 1770X3810 133 3.75 240孔 1770X4150 133 3.75 260孔 1770X4490 133 3.75 280孔 1770X4830 133 3.75 300孔 1770X5170 133 3.75 360孔 1770X6190 133 3.75 400孔 1770X6870 133 3.75 Processing Method of Dust Collector Board

1. Stamping processing

Stamping processing is processed by mechanical or hydraulic equipment. The advantages are high precision, smooth hole wall and low cost. Our company processes dust collector plates all the year round.

2. Laser cutting

Laser cutting is the use of high-power high-speed laser cutting, the advantage is that the plate is not easy to deform, the hole wall is smooth. The disadvantage is that the precision is low, the plate must meet the technical requirements, and the speed is slow.

3. Milling machine processing

Milling machine processing is the use of large milling machine with drilling processing, the advantages of hole wall is smooth, not easy to deformation. The disadvantage is that the processing accuracy is relatively low and the speed is very slow, and the relative cost is very high.

In summary, the use of stamping processing.

According to my company for many years of practical production experience, we concluded that if the dust collector plate hole and hole interval between too close, it will lead to dust bag bottom collision between each other, causing wear. When the operation reaches a certain level, the bottom of the dust collector bag will break, which will also lead to the acceleration of the rising speed of the airflow in the box, so that the emission of smoke and dust will increase.

Dust removal board not only to bear the negative pressure of the system, but also to bear the weight of the dust bag, dust layer and dust removal skeleton. The deformation of the board is likely to affect the verticality of the filter bag and the sealing effect at the mouth of the bag. When designing the board, we should strengthen the lower part of the board, which is a problem that we must pay attention to when designing and making.

Key words:

Pulse dust collector perforated plate

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products